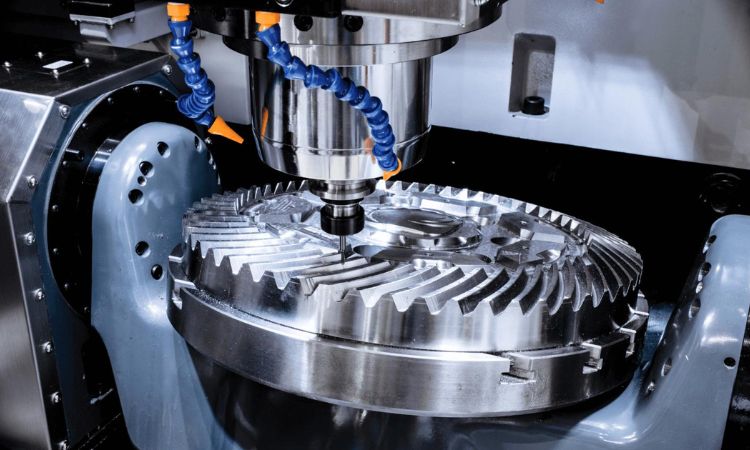

The global milling machine market size attained a value of USD 84.26 billion in 2024. The market is expected to grow at a CAGR of 7.2% in the forecast period of 2025-2034, reaching USD 157.02 billion by 2034. As industries demand more precision and automation, milling machines play a crucial role in manufacturing processes. From automotive to aerospace, construction, and more, the evolution of milling machines is directly influenced by technological advancements and increasing industry needs. This blog post explores the factors driving the growth of the milling machine market, its segmentation, regional trends, and overall market dynamics, offering a comprehensive outlook on the industry’s future.

Market Segmentation

By Mechanism

Fraction Rice Milling Machine

Fraction rice milling machines efficiently separate rice husks, bran, and germ to produce polished white rice. Rice processing plants widely use these machines, and the food processing industry is gaining popularity for them. As global demand for high-quality rice increases, the market for fraction rice milling machines is expected to grow.

Automation and smart features, such as moisture sensors and automated control systems, are driving growth in this segment. People recognize fraction rice milling machines for their efficiency, energy conservation, and improved output quality, which makes them an attractive choice for both large-scale manufacturers and smaller producers in emerging markets.

Grind Rice Milling Machine

Grind rice milling machines process rice into fine flour, which is used in various food products. As rice-based products like rice noodles, rice cakes, and rice flour in gluten-free foods gain popularity, the demand for grind rice milling machines is rising.

With an increasing preference for healthier and more sustainable food options, rice flour’s role in food formulations is expanding.

By Direction

Vertical Type Mill Rollers

Vertical mill rollers are known for their compact design and efficient performance. The vertical orientation allows for better force distribution and energy transfer, making them ideal for industries that need precision in limited space.

Industries like automotive and aerospace, which demand high precision and efficiency, prefer vertical type mill rollers. These machines are also versatile, handling various materials such as metals, plastics, and composites, which makes them a valuable asset in manufacturing and construction equipment sectors.

Horizontal Mill Rollers

Horizontal mill rollers are commonly used for large-scale milling operations, where high throughput and processing capacity are essential. These machines are used in industries requiring high-volume material processing, such as automotive, construction, and industrial machinery production.

Horizontal mill rollers are ideal for manufacturing large workpieces and handling demanding milling tasks. Their ability to provide higher production volumes efficiently makes them a preferred choice for industries focused on mass production and operational efficiency.

By End Use

Automotive

The automotive industry relies heavily on milling machines for producing precise components such as engine parts, transmissions, and other critical components. Milling machines ensure high accuracy in shaping complex parts that meet stringent performance and safety standards. The increasing demand for electric vehicles (EVs) and fuel-efficient cars is driving the need for innovative automotive parts, further pushing the demand for high-precision milling machines.

As the automotive sector continues to innovate, particularly in terms of design and performance, the demand for advanced milling machines capable of producing intricate parts at high volumes will grow.

Aerospace and Defence

Aerospace and defense industries require highly precise parts for aircraft, missiles, and defense equipment. Components like turbine blades, engine parts, and structural components are often produced using advanced milling technologies. The increasing complexity of aerospace designs and the growing demand for defense technologies are driving the growth of the milling machine market in these sectors.

The aerospace and defense sectors require specialized milling machines that can work with high-strength alloys and advanced materials, further fueling the demand for high-performance milling machines in this market.

Construction Equipment

Milling machines are essential in the construction equipment industry, where they are used to produce durable, high-quality components for machinery such as cranes, excavators, and bulldozers. The growing demand for infrastructure development, particularly in emerging economies, is driving the need for efficient manufacturing processes that rely on advanced milling machines.

As construction projects continue to expand globally, particularly in developing regions, the demand for milling machines in the construction sector will rise. Manufacturers are focusing on machines that offer high precision and greater energy efficiency. Allowing for reduced operational costs and improved product quality.

Others

Apart from automotive, aerospace, and construction, milling machines also find applications in electronics, medical devices, and energy production. These industries require high-precision parts, such as semiconductors, medical implants, and turbine components, all of which are often produced using advanced milling technologies. As these industries continue to evolve and grow, the demand for milling machines in these niche markets will also increase.

Regional Analysis

Asia-Pacific

The Asia-Pacific region is expected to be the fastest-growing market for milling machines during the forecast period. Rapid industrialization in countries like China, India, Japan, and South Korea is driving the demand for advanced manufacturing equipment, including milling machines. The region is also home to major manufacturing hubs catering to industries like automotive, aerospace, and construction. With investments in infrastructure development increasing, the demand for milling machines in Asia-Pacific will rise significantly in the coming years.

North America

North America remains a key player in the milling machine market. With the United States and Canada contributing significantly to demand. The aerospace, automotive, and defense sectors in this region are key drivers of the milling machine market. As they require high-precision components for complex and critical parts.

Europe

Europe continues to be a strong market for milling machines, particularly in countries like Germany, Italy, and France. The automotive and aerospace industries are significant contributors to the demand for high-quality milling equipment. Additionally, Europe’s focus on sustainability and energy-efficient technologies in manufacturing will play a key role in the growth of the milling machine market in the region.

Latin America and Middle East & Africa

The Latin American and Middle Eastern markets for milling machines are emerging. With countries in these regions investing in infrastructure projects and industrial development. As industries such as automotive, defense, and construction grow, the demand for milling machines will also rise. The increasing need for high-precision components in these sectors will contribute to the expansion of the milling machine market in these regions.

Market Dynamics

Drivers

- Technological advancements in milling machine automation and precision.

- Growing demand across industries like automotive, aerospace, and construction.

- Increasing focus on energy-efficient and cost-effective manufacturing solutions.

Restraints

- High initial investment costs for advanced milling machines.

- Complexity in operations and maintenance requirements.

Opportunities

- Expanding emerging markets, particularly in Asia-Pacific and Latin America.

- Increasing demand for customized milling solutions.

- Advancements in Industry 4.0, such as AI integration and smart manufacturing.

Competitive Landscape

The global milling machine market is highly competitive, with key players such as DMG Mori, Mazak Corporation, Siemens AG, and FANUC Corporation leading the way. These companies focus on product innovations, strategic acquisitions, and partnerships to expand their market share. The integration of AI, IoT, and automation technologies into milling machines is becoming a key differentiator among manufacturers.