In recent years, the demand for sustainable and eco-friendly packaging solutions has skyrocketed as consumers and businesses alike become increasingly concerned about environmental issues. Traditional packaging materials such as plastic have long been a major source of pollution, contributing to the growing global waste problem. In response, the packaging industry has turned to alternative materials that offer both functionality and sustainability. One of the most promising materials leading this charge is moulded pulp. This article explores how moulded pulp is transforming the packaging landscape and why it is considered a game-changer in the quest for more eco-friendly packaging solutions.

What is Moulded Pulp?

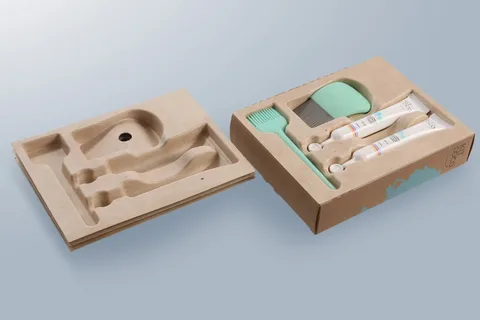

Moulded pulp is a sustainable material made from natural fibers such as recycled paper, cardboard, or other plant-based resources. It is created by combining these fibers with water to form a pulp, which is then molded into a variety of shapes and sizes. Once molded, the pulp is dried, and the resulting product is durable, lightweight, and biodegradable. The material has been around for decades, primarily used in the production of egg cartons and fruit trays, but its applications have expanded significantly in recent years.

Moulded pulp is often seen as a promising alternative to plastic due to its eco-friendly properties. Unlike plastic, which can take hundreds of years to decompose, moulded pulp breaks down naturally in a short period of time, reducing its environmental impact. It can be recycled and repurposed multiple times, contributing to a circular economy. This inherent sustainability has led to a surge in interest from companies seeking to align their packaging with environmentally-conscious values and reduce their carbon footprint.

Moulded Pulp and the Push for Sustainable Packaging

As environmental concerns mount, businesses and governments around the world are putting increasing pressure on companies to reduce their reliance on single-use plastics. Moulded pulp presents a viable solution to this problem, offering an alternative that is both functional and environmentally responsible. Many companies in industries such as food and beverage, electronics, and cosmetics are now turning to moulded pulp for their packaging needs. This shift is not only driven by consumer demand but also by legislation aimed at reducing plastic waste.

One of the key advantages of moulded pulp is its ability to mimic the protective qualities of plastic. It can be molded into custom shapes, offering a high level of protection for fragile items during transportation. This makes it an ideal choice for packaging products such as electronics, cosmetics, and food items. Additionally, the material is incredibly versatile, with manufacturers able to produce a wide range of products, from protective inserts to fully formed packaging containers. The ability to create custom shapes and sizes makes moulded pulp an attractive option for businesses looking for sustainable packaging solutions.

The Environmental Benefits of Moulded Pulp

The environmental benefits of moulded pulp are numerous, making it an increasingly popular choice for eco-conscious brands. Unlike plastic, which is derived from petroleum, moulded pulp is made from renewable, plant-based resources. Many manufacturers use recycled paper or cardboard in the production of moulded pulp, further reducing the material’s carbon footprint. Additionally, the production process for moulded pulp is less energy-intensive compared to plastic manufacturing, contributing to its overall environmental advantages.

Furthermore, moulded pulp is biodegradable and compostable. This means that if the packaging is not recycled, it will naturally break down and return to the earth without leaving behind harmful pollutants. In contrast, plastic can take hundreds of years to degrade, during which time it can release toxic chemicals into the environment. By choosing moulded pulp over plastic, companies are making a significant contribution to reducing plastic pollution and promoting a more sustainable future. This is especially important as governments and organizations around the world implement stricter regulations on plastic use and waste management.

How Moulded Pulp Enhances Brand Reputation

As sustainability becomes an increasingly important issue for consumers, brands are under growing pressure to adopt eco-friendly practices. Using moulded pulp for packaging is one way that companies can demonstrate their commitment to environmental stewardship and differentiate themselves in a crowded marketplace. Consumers are more likely to support brands that align with their values, and many are now actively seeking out products with sustainable packaging.

Incorporating moulded pulp into packaging also offers a unique marketing opportunity. Brands can highlight the eco-friendly nature of their packaging in their advertising, which can resonate with environmentally-conscious consumers. This can lead to increased brand loyalty and positive consumer perception, which is invaluable in today’s competitive market. As more and more consumers prioritize sustainability, adopting moulded pulp packaging can be a key factor in attracting new customers and retaining existing ones.

Challenges and the Future of Moulded Pulp Packaging

While the potential of moulded pulp is clear, there are still some challenges to overcome before it can completely replace plastic packaging on a global scale. One of the main challenges is the production cost. While moulded pulp is generally less expensive than high-end plastic alternatives, it can still be more costly than conventional plastic packaging for certain products. The process of creating moulded pulp products requires specialized equipment, and depending on the material used, the production can be more labor-intensive.

Additionally, the quality and durability of moulded pulp may not always meet the expectations of consumers, especially in industries where packaging performance is critical. For instance, in the food industry, the material must be able to withstand moisture and temperature fluctuations without losing its integrity. While advances in technology are improving the durability and versatility of moulded pulp, further innovation is needed to expand its applications and improve its performance in various sectors.

Looking ahead, the future of moulded pulp in eco-friendly packaging is bright. As consumer demand for sustainable products continues to rise, and as more brands seek to reduce their environmental impact, moulded pulp is poised to play a significant role in the packaging industry. Continued advancements in production techniques and materials will likely drive down costs and improve the performance of moulded pulp packaging, making it a more viable option for businesses worldwide. The growth of circular economies and sustainability initiatives also supports the rise of this eco-friendly alternative, signaling a positive shift toward more sustainable packaging solutions in the coming years.

Conclusion

In conclusion, moulded pulp is revolutionizing the eco-friendly packaging industry by offering a sustainable, versatile, and biodegradable alternative to plastic. Its environmental benefits, combined with its ability to provide protection and customizability, make it an attractive option for businesses looking to reduce their environmental impact. As demand for sustainable packaging grows, moulded pulp is poised to become a key player in reshaping the future of packaging, offering a practical solution that meets both consumer needs and environmental goals. With ongoing advancements and wider adoption, the future of moulded pulp in packaging looks incredibly promising, paving the way for a greener and more sustainable world.