Lobe pumps play a pivotal role in industries where the handling of viscous fluids is crucial. Their ability to provide steady, reliable flow while maintaining the integrity of the fluid makes them indispensable in applications such as food processing, pharmaceuticals, and chemical manufacturing. The design of the lobe pump and its operational characteristics allow it to deliver consistent performance, even when working with high-viscosity liquids.

This article explores how lobe pumps function and why they are particularly well-suited for viscous fluids. We will delve into their working principles, key advantages, maintenance requirements, and applications. By the end, you will have a thorough understanding of why lobe pumps are a preferred choice for industries dealing with challenging fluid types.

Understanding the Basic Working Principles of Lobe Pumps

Lobe pumps are positive displacement pumps that utilize rotating lobes to move fluids through the pump chamber. The lobes rotate in opposite directions, trapping fluid between them and the pump casing. As the lobes rotate, they create a vacuum that draws in the fluid and then pushes it out in a continuous flow. This unique mechanism allows for precise and consistent fluid movement, especially in systems where the viscosity of the liquid may vary.

For viscous fluids, this pumping mechanism is highly beneficial. The lobe pump’s design minimizes shear forces and ensures that the fluid retains its properties, even under high-pressure conditions. The gentle handling of the fluid makes it particularly effective for substances like pastes, slurries, syrups, and creams, which can be damaged by other types of pumps that apply excessive shear or pressure.

The Key Advantages of Lobe Pumps for Viscous Fluids

Lobe pumps offer several advantages that make them the go-to solution for pumping viscous fluids. One of the main benefits is their ability to handle thick and sticky substances without clogging. Unlike centrifugal pumps, which rely on the speed of rotation to move fluid, lobe pumps rely on mechanical displacement, which means they can handle higher viscosities without sacrificing performance.

Another major advantage is their flow rate consistency. Lobe pumps deliver a uniform flow of fluid with minimal pulsation, even at lower speeds. This is especially important when pumping shear-sensitive or abrasive fluids, as the consistent flow prevents damage to both the pump and the fluid. The ability to maintain steady performance without fluctuations in pressure or flow ensures that the entire system operates smoothly and efficiently, even with fluids that are harder to pump.

Lobe Pump Design Features for Enhanced Performance

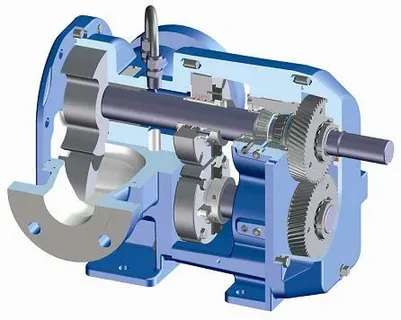

The design of a lobe pump is critical to its performance, especially when handling viscous fluids. Lobe pumps are available in a variety of configurations, but the key feature across all designs is the inclusion of two or more rotors or lobes. These lobes can be made from various materials such as stainless steel, plastic, or rubber, depending on the fluid’s properties and the application’s requirements.

The spacing between the lobes and the casing is engineered to create a seal that minimizes fluid leakage. This ensures that the fluid is moved efficiently without any loss. Additionally, lobe pumps are equipped with multiple seals, bearings, and advanced mechanical parts that reduce the wear and tear typically associated with high-viscosity pumping. These design elements contribute to the longevity and reliability of the pump, making it a durable solution in industries where continuous, high-performance pumping is necessary.

Maintenance Considerations for Lobe Pumps

Maintaining a lobe pump is essential to ensure consistent performance over time. Regular inspection and maintenance help to prevent issues such as blockages, wear on the lobes, and seal degradation, all of which can compromise the pump’s efficiency. One of the main reasons why lobe pumps require less maintenance than other types of pumps is their robust construction and fewer moving parts. However, it’s still important to monitor the seals, bearings, and lubrication regularly.

For viscous fluids, which can cause buildup or clogging over time, proper cleaning is crucial. Many lobe pumps come with easy-to-clean designs, such as sanitary versions with smooth surfaces and removable parts. This feature is particularly useful in industries like food processing or pharmaceuticals, where hygiene and cleanliness are a top priority. By following a scheduled maintenance plan, companies can ensure that their lobe pumps continue to perform reliably, even under demanding conditions.

Applications of Lobe Pumps in Viscous Fluid Handling

Lobe pumps are versatile and can be found in a wide range of industries that require the handling of viscous fluids. In the food and beverage sector, for example, they are used to pump oils, syrups, and sauces without breaking down the product’s texture. Their gentle pumping action helps preserve the quality and consistency of the fluid, which is vital for maintaining the integrity of food products.

In addition to food processing, lobe pumps are also essential in industries such as pharmaceuticals, chemicals, and cosmetics. These pumps are used for transporting creams, lotions, pastes, and adhesives, all of which have high viscosities and require careful handling. The ability of lobe pumps to operate without disrupting the fluid’s properties ensures that the final product is of the highest quality, with minimal risk of contamination or degradation.

In conclusion, lobe pumps are essential for ensuring the smooth, consistent, and efficient transfer of viscous fluids. Their unique design and operational principles make them the ideal choice for industries where fluid integrity and flow consistency are paramount. Whether it’s in food processing, pharmaceuticals, or chemical manufacturing, lobe pumps provide a reliable solution for moving thick and sticky substances. With proper maintenance and attention to design features, these pumps can provide long-term, dependable service in even the most challenging applications.